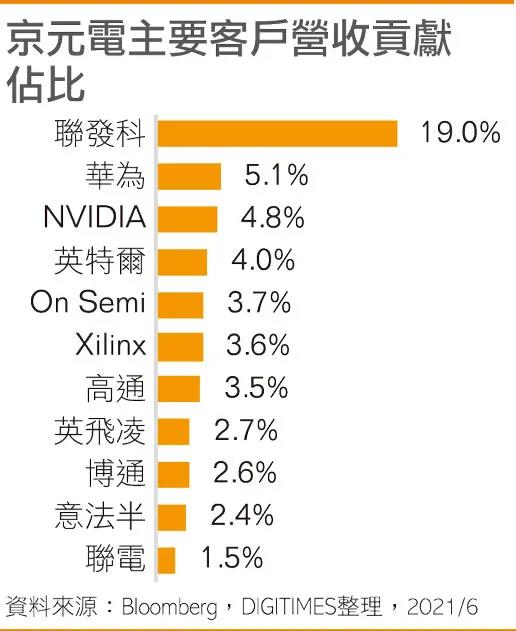

KYEC holds a large number of international first-line IC design and IDM industry test orders. The current largest customer is MediaTek, the leading Taiwanese company. In the past, the major customer was Huawei HiSilicon. In addition, it also includes American Qualcomm (Qualcomm), 5G, RF chip leader Skyworks, Broadcom (Broadcom), high-efficiency computing chip (HPC) NVIDIA, Intel (Intel), Xilinx (XilinX), sensor-related Italian law Semiconductor (ST), Howe (OVT), etc. With the outbreak of migrant workers infected with the epidemic, the market is concerned about whether it will affect the fluency of global semiconductor chip supply.

The packaging and testing industry executives stated that it is a difficult challenge to balance the epidemic prevention and industrial development, especially among the more than 7,300 employees of KYEC, about 27-28% are foreign migrant workers, although there are still some in the wafer test (CP) section. Automated equipment assists, but later finished product testing (FT), product packaging and shipment from warehouses, etc., require high human resources. If foreign migrant workers are completely shut down, the impact on business operations will be significantly enlarged.

In fact, those familiar with IC test industry bluntly say that semiconductor test equipment needs to be strictly certified, and the test factory has to undertake new customer IC tests that have never been done before. It is unlikely to be transferred and achieved in a short period of time, unless the customer’s products are originally at the same time. A number of testing suppliers have been found to cooperate to adjust the proportion, and the proportion of orders from certified companies is expected to increase.

In addition, the Taiwan-based IC packaging and testing industry is currently operating at a high speed, and the packaging section of the previous section is almost full. In terms of the IC production process, it is the turn of the test industry to fully load after 1 to 2 months. Starting from the second quarter, as the demand for 3C and automotive electronic chip testing is increasing, KYEC and other testing companies are part of the semiconductor supply chain. In addition, foreign employees and local employees are mostly concentrated in Miaoli and Hsinchu. First-line chip customers are also paying close attention to follow-up development.

In addition, packaging factory Chaofeng and Netcom factory Zhibang each have 12 confirmed cases. The super fast screening is also ongoing and is expected to be completed before Tuesday. It is worth noting that Chaofeng is holding large packaging orders from Taiwanese chip manufacturers such as Nuvoton, Shengqun, Songhan, Hongkang, and Weiquan Electronics. In particular, the MCU has recently been heavily congested due to the packaging and testing process, and the delivery date is frequently delayed. It is even delayed for another 1 to 2 months. About 25% of Chaofeng’s workforce is foreign migrant workers. If the suspension measures are also implemented in Chaofeng, the follow-up MCU supply situation may become increasingly severe.

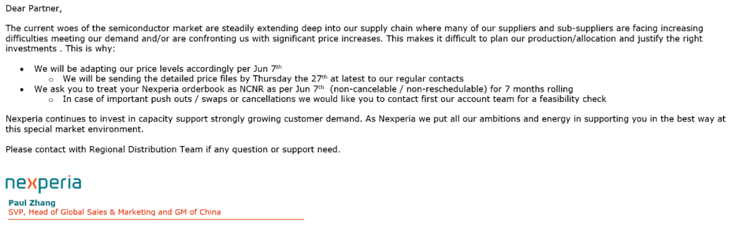

Anshi Semiconductor: price increase from June 7

Recently, Nexperia issued an increase notice to customers. Nexperia said that due to the impact of the new crown pneumonia, semiconductor wafers, foundries and packaging are facing raw material shortages and increased costs. The cost of Nexperia's products is also increasing. Therefore, it has decided to increase on June 7, 2021. The price of the product.

According to supply chain sources, the current shortage of Nexperia Semiconductor in the market is not serious, but spot inventory prices have been rising slightly. It should be noted that entering June, the original factory shipment prices have risen sharply, by as much as 30%-40%.

Taiwan, as a global foundry and packaging and testing center, if the epidemic cannot be effectively controlled as soon as possible, it may severely impact the global semiconductor production chain. At present, the shortage of foundry capacity has caused a global semiconductor supply crisis. The lack of core has severely affected the production and manufacturing of end products in many fields such as automobiles and consumer electronics. If the packaging and testing capacity that is already in short supply is lost, it will undoubtedly Further exacerbate the global core shortage and price increase problems.

Previous:

Next :